First of all, it needs to confirm the demand for the data in the project, so as to decide the type of fiber-optical backbone

To determine the amount of information and bandwidth of the network, it should calculate the number of information points according to the customer's needs at first. Assuming that 50% of information points are in use at the same time and each subscriber will occupy 20M bandwidth, the bandwidth demand of the current weak current information backbone can be obtained according to the number of information points. According to the calculated the amount of data, the number of cores required to lay the fiber-optical can be obtained. It is worth noting that 100% redundant backup should be considered for the backbone system in the design of the fiber-optical backbone of the integrated cabling system.

Next, determine the type and quantity of fiber-optical:

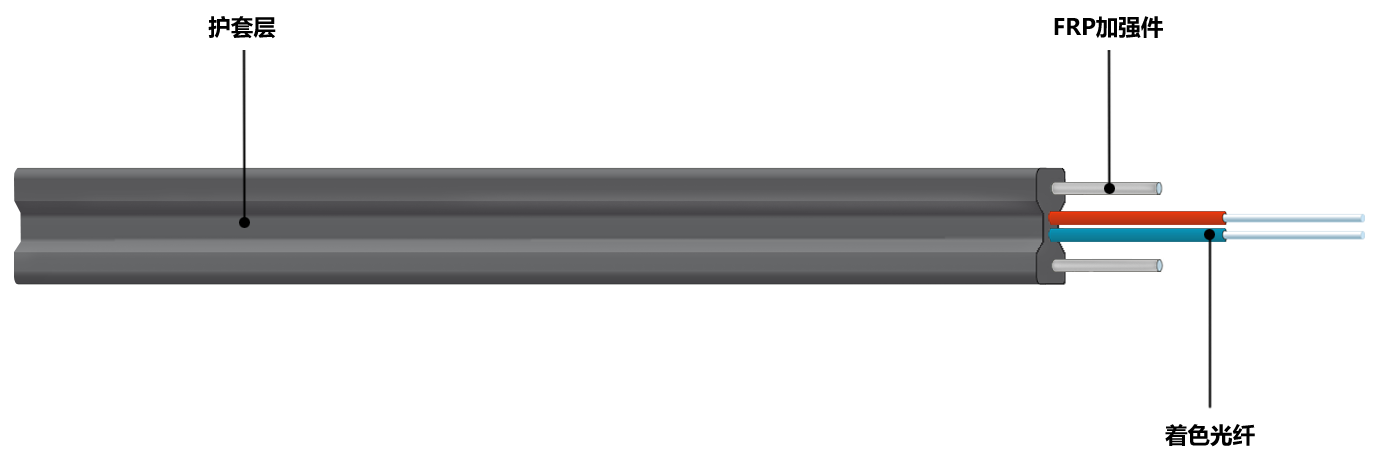

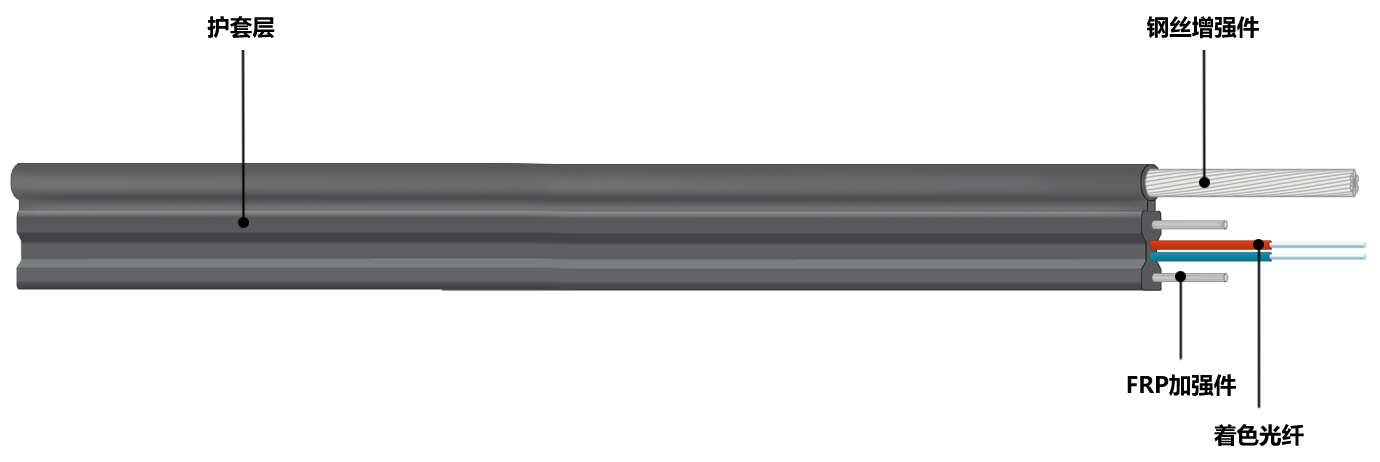

( 1 ) Determine the type of fiber-optical according to the laying position of fiber-optical: indoor / outdoor / indoor & outdoor / armored, etc.

( 2 ) According to the transmission distance, transmission speed and other aspects, determine multi-mode ( OM1 / OM2 / OM3 ) / single mode.

( 3 ) According to the connector requirements, determine the type of fiber-optical such as LC/SC.

( 4 ) Determine the length of fiber-optical according to the cabling structure and site conditions: length = ( number of layers from the main distribution frame x height + distance from weak point wells to the main distribution frame + terminal tolerance ) * number of required fibers per layer; Note: The part of fiber-optical in the terminal tolerance is 10m.

( 5 ) according to the fire prevention requirements, determine whether the fiber sheath is low smoke and halogen free.

At present, for the network structure, it mainly adopts hierarchical star-shaped structure, and the network is divided into two levels.

The first level is the network center, which is the central node. It arranges the core equipment of the network, such as routers, exchange board, servers ( WWW servers, e-mail servers ) and reserves external communication interfaces.

The second level is the exchange board between the wiring, which is the second level node. The fiber-optical backbone is set up in the building as the data transmission trunk, from the core layer to the secondary node, and is terminated between distribution lines. The secondary exchange board can adopt Ethernet or Fast Ethernet exchange board that connects to the backbone exchange board in the center of the network up and to the server and workstation down directly.

According to the above network structure, we also adopt star-shaped structure design in the integrated cabling system. The star-shaped physical structure is the most flexible physical structure. It can form different logical structures through different adapters or network devices, which is not only suitable for the needs of telephone systems, but also for the requirements of computer networks and other intelligent systems. The whole structure is roughly divided into two levels of star-shaped and trunk and horizontal sections. The star-shaped structure center of the trunk section is located in a weak current access room on the first floor and radiates to each floor, while the medium uses fiber-optical and multi-pair twisted-pair respectively. The star-shaped center of the horizontal part is in the floor cabling room, and the horizontal twisted-pair is led out from the distribution frame to each information point. The center of the star-shaped structure are all management subsystems, and it can realize the connection, configuration and flexible application of the whole cabling system through a two-point management method.

In addition, considering that the network system may be designed into several network segments ( such as external network, office network, management network, weak current network, etc. ) that need the physical separation according to customer requirements. Similarly, the integrated cabling system should physically separate cabling according to application.

For modern office buildings, IP phones are being used more and more in practical work. For integrated cabling systems, the information transmission of IP phone will also be undertaken by the fiber-optical backbone, without the need to set up the traditional multi-pair copper cable. For some devices that still need analog transmission like fax machine, they can be converted to TCP / IP method through gateway devices.

Structure of Fiber-optical Backbone System in Data Room

Set up a main distribution area ( MDA ) in the data room or data center. Network equipment, servers, and fibers-optical aggregated in the building's main distribution frame ( MDF ) are again aggregated into the main distribution area in the computer room or data center. Through the optical fibers-optical jumpers between the main distribution areas, the jumpers between the devices are completed.

A relatively fixed pre-connected optical cable is recommended to be used between the main distribution frame and the equipment cabinet to avoid the confusion of jumpers caused by direct jumpers between equipment and the conditions of frequently plugging and unplugging jumpers on equipment.

A high-density distribution frame can be used in the main distribution area, for example, the space of 5HU reaches the distribution function of 288-core, and the product structure adopts a modular structure. The trunk fiber-optical is pre-connected optical cable, which does not need to be terminated on site. So when the system expands capacity, it only needs to be directly terminated with the connector of pre-connected optical cable, and the trunk adopts MPO connector and directly plugged with modules, so as to save the overall installation time and facilitate the maintenance of the computer room.

a.aerial optical cable

The aerial cable is an optical cable hung on a pole. This laying method can use the original overhead open-circuit pole road, save the construction cost and shorten the construction period. The aerial cable is hung on the pole and is required to adapt to various natural environments. The aerial cable is vulnerable to the threaten of natural disasters such as typhoons, ice and floods, as well as external forces and weakening of its own mechanical strength. Therefore, the failure rate of aerial cable is higher than that of direct burial fiber cable and duct optical cable. It is generally used for long distance secondary or sub-secondary lines, and is suitable for special network optical cable lines or some local special sections.

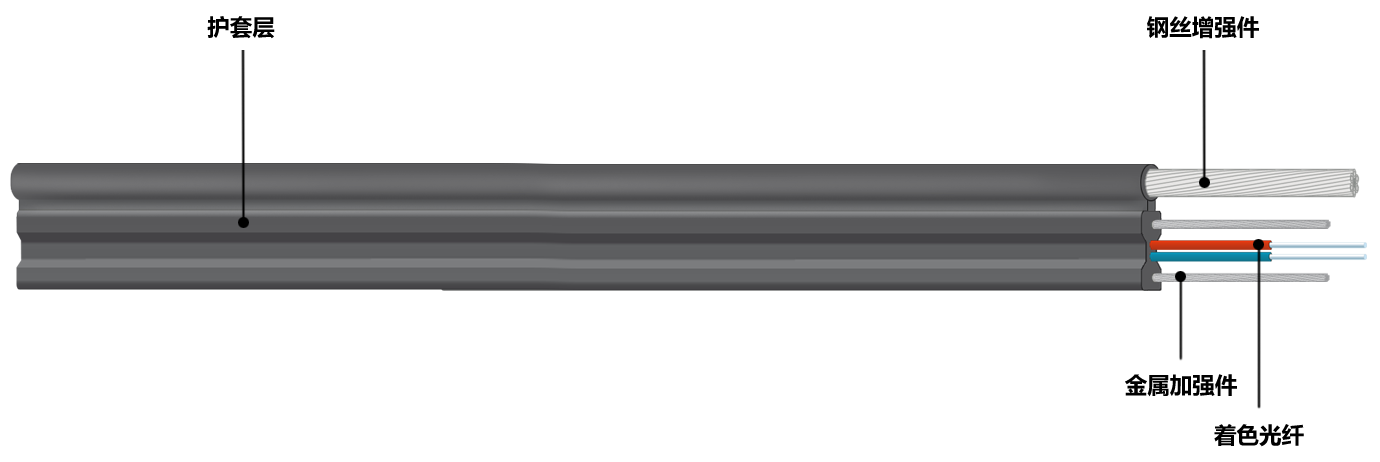

b. direct burial fiber cable

This kind of optic cable has steel belt or steel wire armouring outside and is directly buried in the ground. It requires the performance of resisting external mechanical damage and preventing soil corrosion. Different protective layer structure should be selected according to different use environments and conditions, for example, in areas with insect and rat infestations, optical cables with protective layer that are bitten by insect and rat infestations should be selected. According to the different soil quality and environment, the buried depth of optical cables is generally between 0.8m and 1.2m. When laying, it must care that the fiber strain should be kept within the allowable limits.

c.duct optical cable

Duct laying is generally in urban areas, and the environment for duct laying is relatively good, so there is no special requirement for cable sheath and no armor required.

The length of the laying section and the position of the connecting point must be selected before laying the duct. When laying, mechanical side guide or manual traction can be used. The traction force of traction in one time should not exceed the allowable tension of the optical cable. The materials used to make ducts can be concrete, asbestos cement, steel pipes, plastic pipes and others according to geography.

d.underwater optical cable

Underwater optical cable is a kind of optical cable that passes through the rivers, lakes, beaches and other places radiating the water. The laying environment of this kind of optical cable is much worse than that of duct laying, and the conditions for direct laying are much worse. The underwater optical cable must adopt the structure of steel wire or steel-tape armouring, and the structure of the cover layer should be comprehensively considered according to the hydro-geological conditions of the river. For example, in rocky soil, the seasonal riverbed with strong scouring property, the wearing of optical cables and the high tensile force require not only heavy steel wires for armouring, but even double-layer armouring. The construction method should also be chosen according to the width of river, depth of water, current velocity, riverbed drawings and others. The laying conditions of underwater optical cables are much more severe than those of direct burial fiber cable, and the techniques and measures to repair faults are much more difficult, so the reliability require by underwater optical cables are also higher than those of direct burial fiber cable.

Submarine optical cables are also underwater cables, but the environmental conditions are more stern and have higher demand than those of ordinary underwater optical cables, and the service life for submarine optical cable systems and their original components is required to be more than 25 years.

According to various applications and environmental conditions, there are various layout method of communication optical cables such as aerial optical cable, direct burial fiber cable, duct optical cable, underwater optical cable and indoor optical cable.

|